Over a century of American Engineering & Manufacturing

At AMB, we proudly carry forward a legacy of American manufacturing excellence. With over 100 years of industry experience, we are dedicated to delivering superior quality and precision in every product we make. From our early beginnings to our role in national defense today, our legacy stands as a testament to the enduring values of excellence and reliability that continue to drive us forward.

Over a century of American Engineering & Manufacturing

At American Metal Bearing, we take pride in our long-standing tradition of American manufacturing excellence. With over a century of experience in the industry, our commitment to quality and precision is unrivaled. Our heritage of craftsmanship and innovation ensures that every product we deliver meets the highest standards of performance and reliability.

Humble Beginnings

American Metal Bearing Company (AMB) began its journey in 1921 when Mr. Wyllis founded the business at the intersection of 3rd Street and Central Avenue in Los Angeles. At the time, AMB’s focus was automotive bearings, serving prominent customers such as Pickwick Stages, today known as Greyhound Bus, and Western Auto Supply Co., a major supplier for Ford Model T connecting rods.

Our founder developed an innovative connecting rod and bearing designed specifically for the legendary Duesenberg race cars. Building on this success, AMB expanded into specialized bearings for Harry Miller racing engines, demonstrating our ability to create precision-engineered components that withstand the extreme demands of competitive racing.

This pioneering spirit established the foundation for AMB’s lasting legacy of exceptional quality, reliability, and performance in bearing manufacturing.

Maritime & Diesel Engine Markets

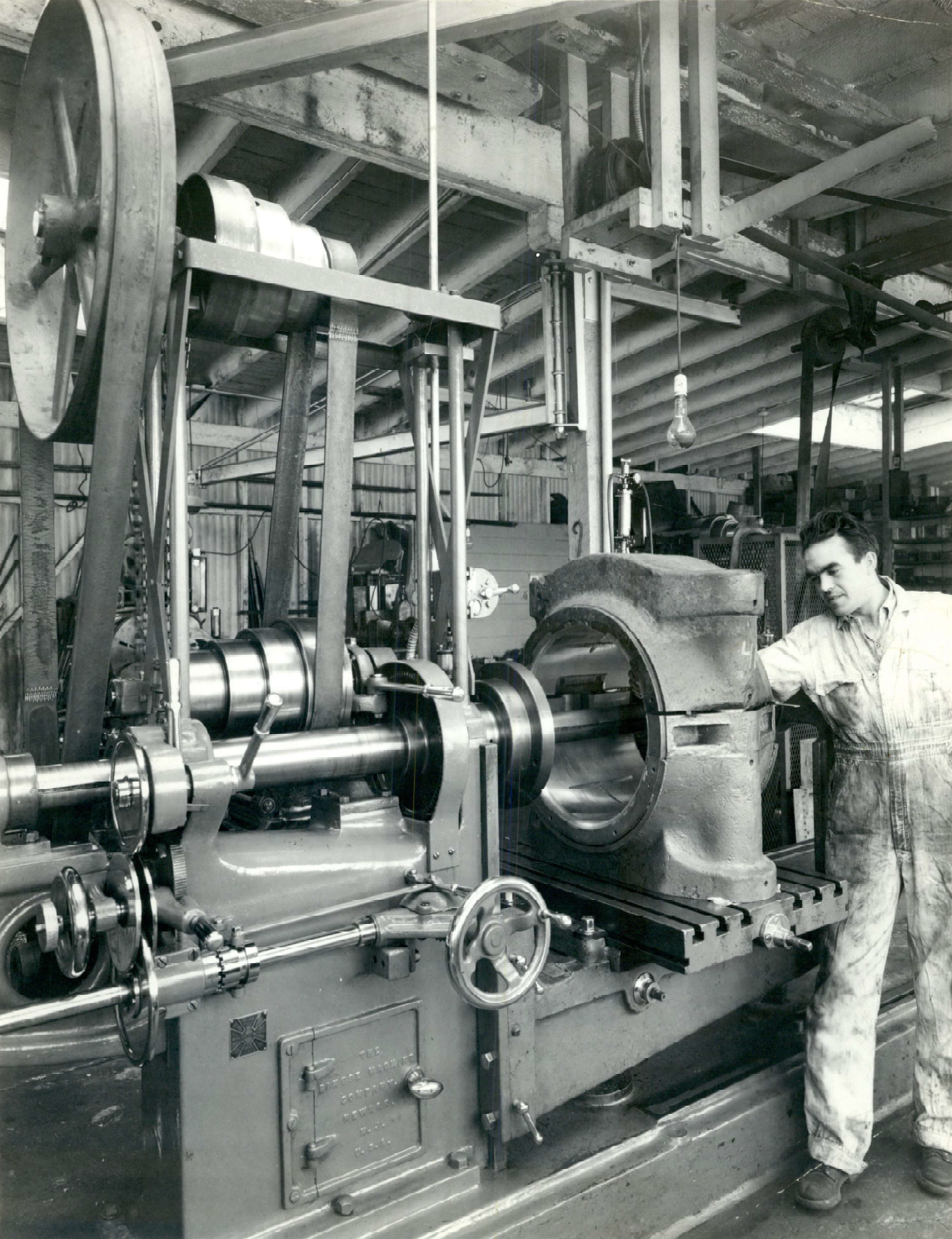

By the 1930s, AMB relocated to a larger facility at 6th and Alameda Street in Los Angeles. It was here that we introduced our proprietary "Weld-Tite" babbitting process, a method of securely bonding babbitt metal to bronze, steel, and cast iron components. This breakthrough quickly established American Metal Bearing Company as an essential partner to the petroleum and maritime industry, directly addressing significant challenges companies faced due to babbitt failures in their large diesel engines.

From Underdog to Key Role In World War II

The onset of World War II led to significant facility expansions, and we swiftly began fulfilling large scale orders for marine line shaft bearings. Among our initial contributions to the war effort were 50 shipsets of line shaft bearings destined for lend/lease ships bound for England. Throughout the war, we manufactured over 7,000 bearings for cargo and naval vessels. This photo shows just eight of twenty five car loads of AMB’s Weldtite Lineshaft Bearings used in the construction of 531 Victory class ships.

Product Line Expansion

Post World War II, AMB’s products were used on most of the US Navy’s large surface combatant programs. Frigates, destroyers, amphibious transport docks, and nuclear submarines all utilized AMB components within their propulsion systems. AMB had expanded its engineering services and began working with prime contractors for their propulsion system needs. In April of 1973, the company moved from its down Los Angeles location to its current location in Garden Grove. By this time, production of marine bearings for commercial and military applications dominated our sales efforts.

Meeting Modern Day Demands

AMB currently operates out of its 50,000 sqft advanced manufacturing facility in Garden Grove, California. We’re able to provide a full range of design and engineering services, applied research and prototyping, and contract manufacturing services.